TKM 900 SRW Compact

This model is entirely constructed from stainless steel, with the mold and aluminum parts coated in eloxal for increased durability. Monitoring of values is made easy, both numerically and graphically, via a touch operator panel, facilitating simple execution of all actions. The pneumatic system is sensor-controlled, providing operator guidance through warning messages displayed on the machine’s interface. This machine comes with options for both printed and non-printed film and includes a photocell system. Its easy-to-replace mold system offers cost-effectiveness, unlimited mold choices, and high performance.

Description

Description

Types of packaging

| Sealing Only |

Packaging products

| Dry Fruits And Snacks |

| Baking |

| Fruits And Vegetables |

| Ready Meals |

| Fresh Meats |

| Cheese And Dairy Products |

| Cold Meats |

| Fresh Noodles |

| Sliced |

| Fish |

Technical Specifications

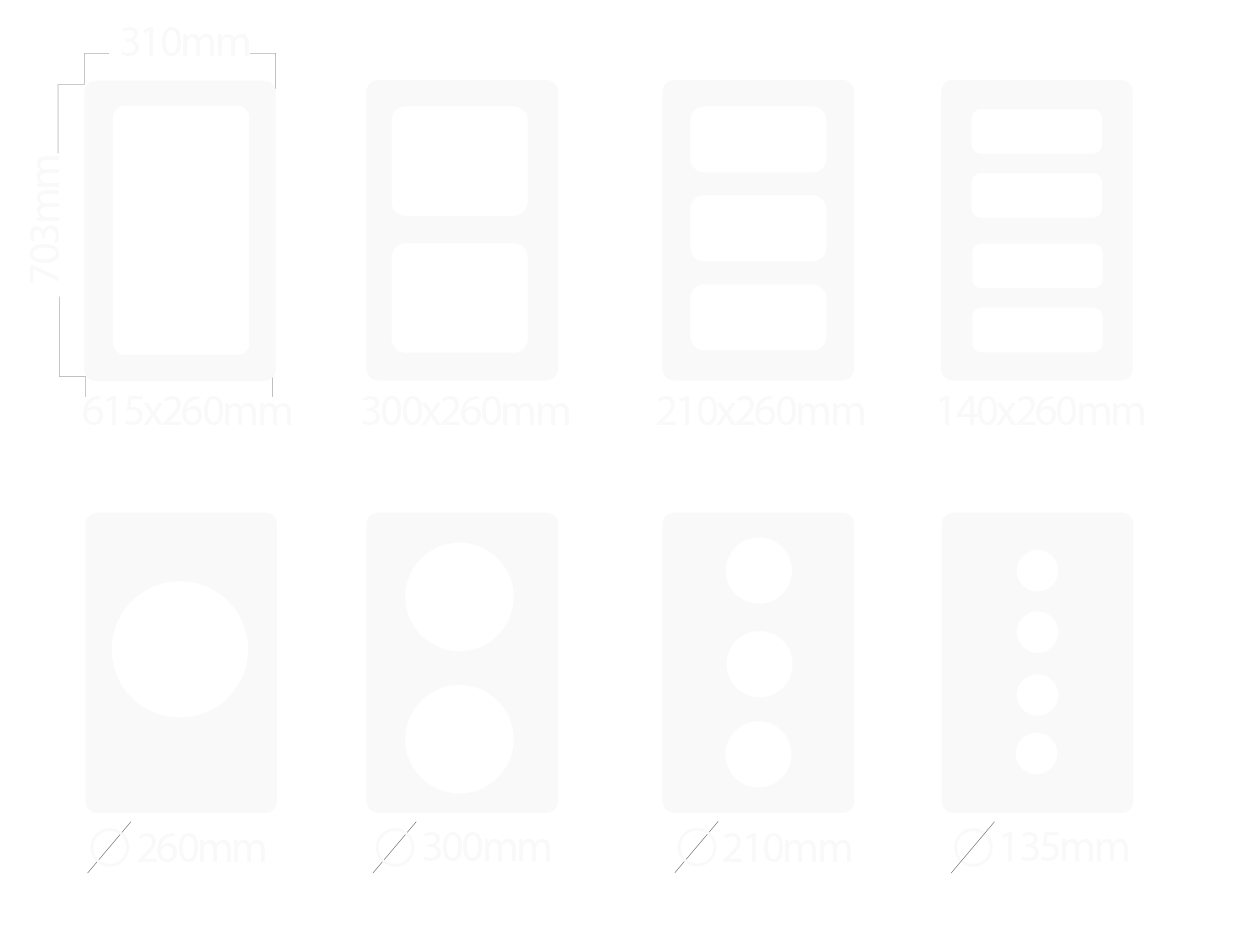

| Tray Options | |

| PP | Yes |

| PET | Yes |

| Paper | Yes |

| Sealing Options | |

| Film | Yes |

| Paper | Yes |

| Skin | No |

| Map | No |

| Vacuum | No |

| Installed Power | 380v 50 Hz 40a R.S.T.N. PE |

| Energy Consumption | 3 Kw |

| Air Pressure | Max 6 Bar |

| Air Consumption | 5.5 Lt Cycle |

| Capacity/min | 10-12 Process |

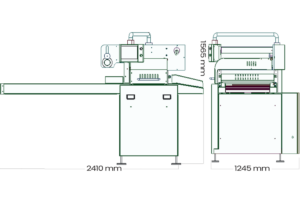

| Machine Dimensions | 2410 X 1245 X 1565+500 mm |

| Max. Mold Dimensions | 703 x 310 mm Standard |

| Weight Net/Packaged | 490 Kg |

| Max. Depth Of Plate | 260 mm |

| Max. Film Width | 7200 Mm |

| Min. Film Thickness | 40 Mic |

| Infeed Band | 1500 mm |

| Discharge Belt Free Roll | 300 mm |

| Max. Film Weight | 16 Kg |

Features

| Line type solution on without vacuum tray sealing |

| Automatic – manual and by step by step options |

| 10-inch Touch Screen operator panel |

| Automatic filling and magazine can be integrated into feed band |

| Precise positioning with servo control loading band |

| Values are monitored numerically and graphically |

| Possibility of only welding and cutting by one-touch |

| Photocell unit to use printed film |

| Eloxal coated aluminum parts |

| Energy saving with automatic temperature control system (PID) |

| Stainless steel body of quality 304 |

| Teflon coated mold system |

| Very easy to transport by stainless steel wheels |

| Automatic film adjustment and waste film discharge system |

| Completely cuts the film around the plate and does not need extra labor |

| Easy to clean and hygienic equipment |

Related products

Reach out to us for a demo.

Speed up your operations with this environmentally responsible, surprisingly affordable, and elegant package.

Artisan Container LLC

3382 Commercial Avenue

Northbrook, IL, 60062

+1 872 248 9470

sales@artisancontainer.com

© ArtisanContainer.Com