Description

Description

The mold and aluminum parts are eloxal coated. Values can be monitored numerically and graphically with the touch operator panel and any action can be done easily. The pneumatic system, gas pressure and vacuum values are controlled by sensors on the machine and operator is directed by warning message on display. The machine has printed film, non-printed film options and photo cell system. It provides unlimited mold choice and high performance with the easy to replace mold system. Safety is provided by CE&EAC standards. It’s automatically switches to stop while installing the film or replacing the mold, by the help of security sensors.

Types of packaging

Packaging products

| Dry Fruits And Snacks |

| Baking |

| Fruits And Vegetables |

| Ready Meals |

| Fresh Meats |

| Cheese And Dairy Products |

| Cold Meats |

| Fresh Noodles |

| Sliced |

| Fish |

Technical Specifications

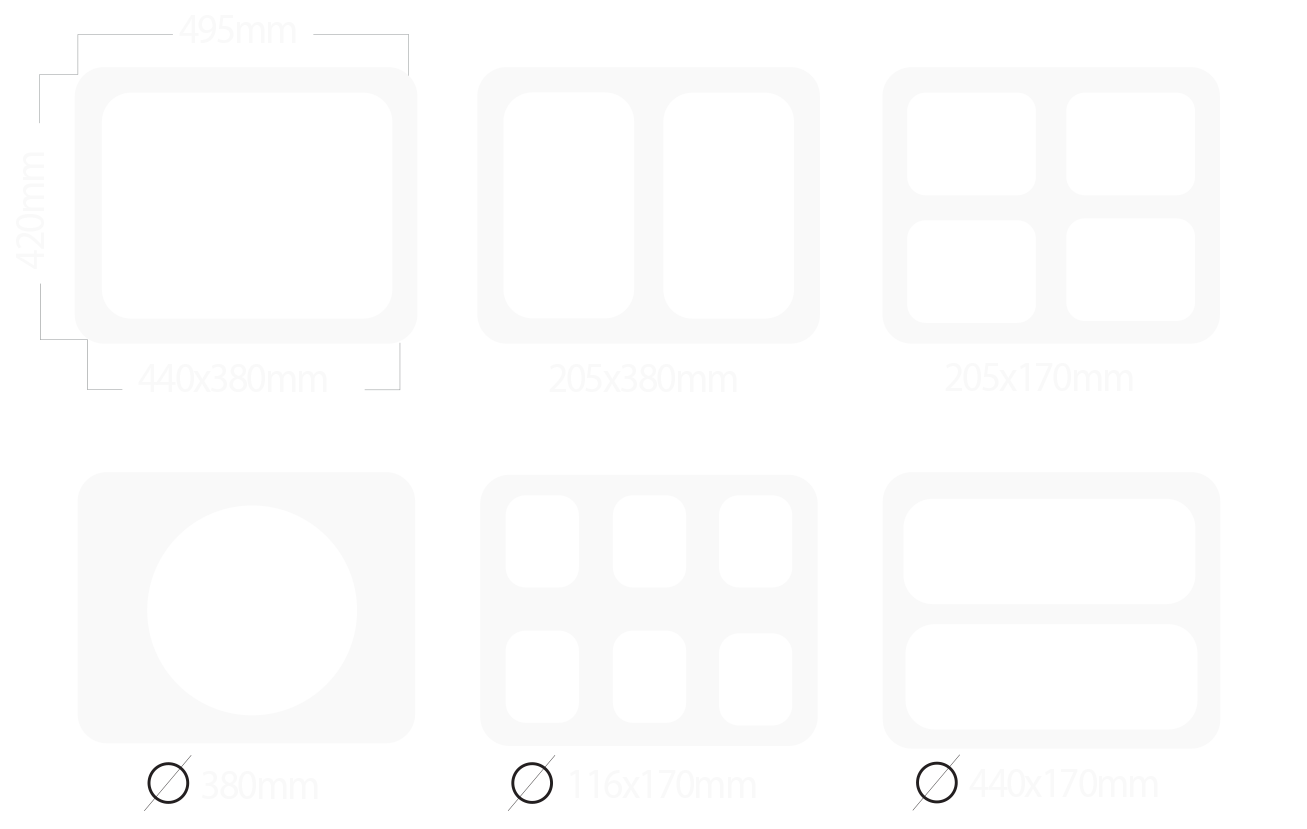

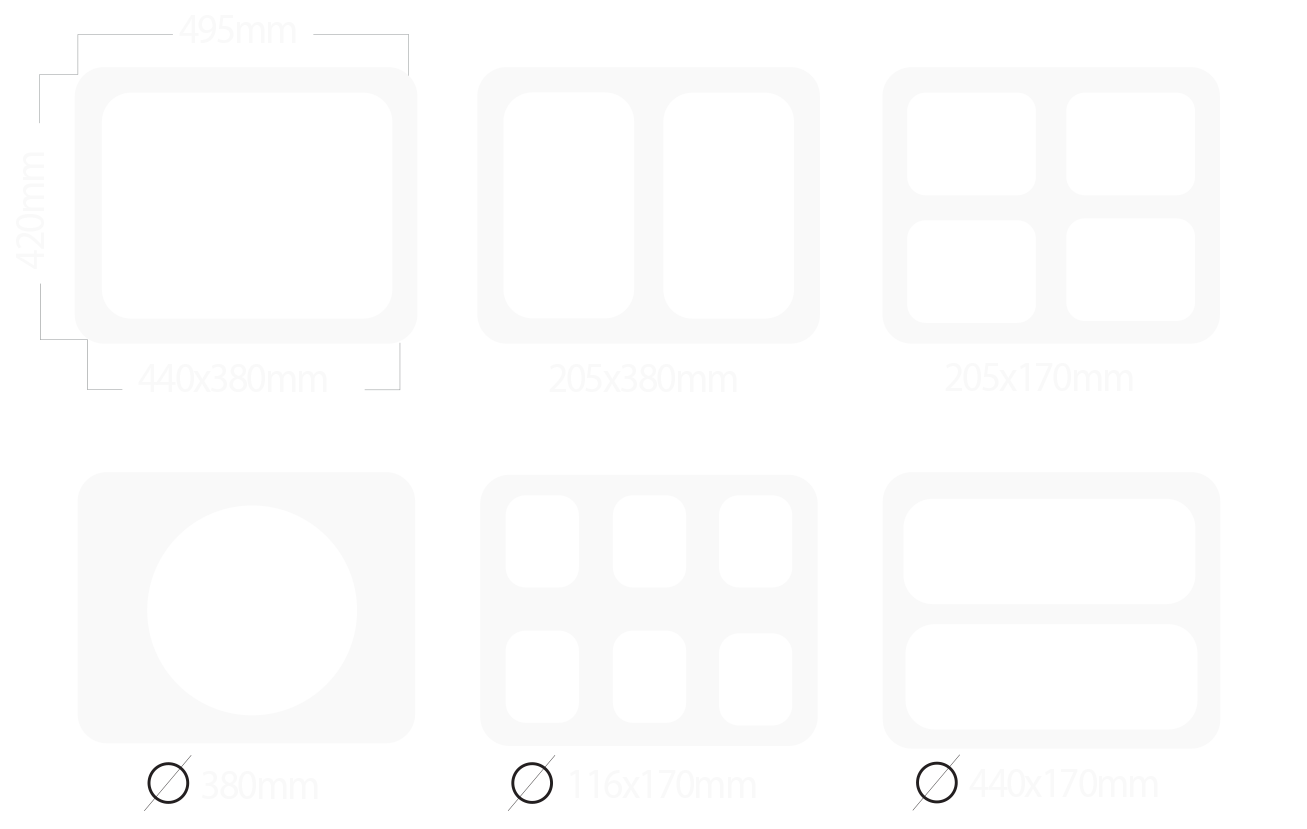

| Tray Options |

|

| PP |

Yes |

| PET |

Yes |

| Paper |

Yes |

| Sealing Options |

|

| Film |

Yes |

| Paper |

No |

| Skin |

No |

| Map |

Yes |

| Vacuum |

Yes |

| Installed Power |

380v 50 Hz, 16 A |

| Vacuum Pump |

100 M3 |

| Energy Consumption |

4 KW |

| Air Pressure |

Max 6 Bar |

| Air Consumption |

10 Lt Cycle |

| Capacity/min |

4-10 Process |

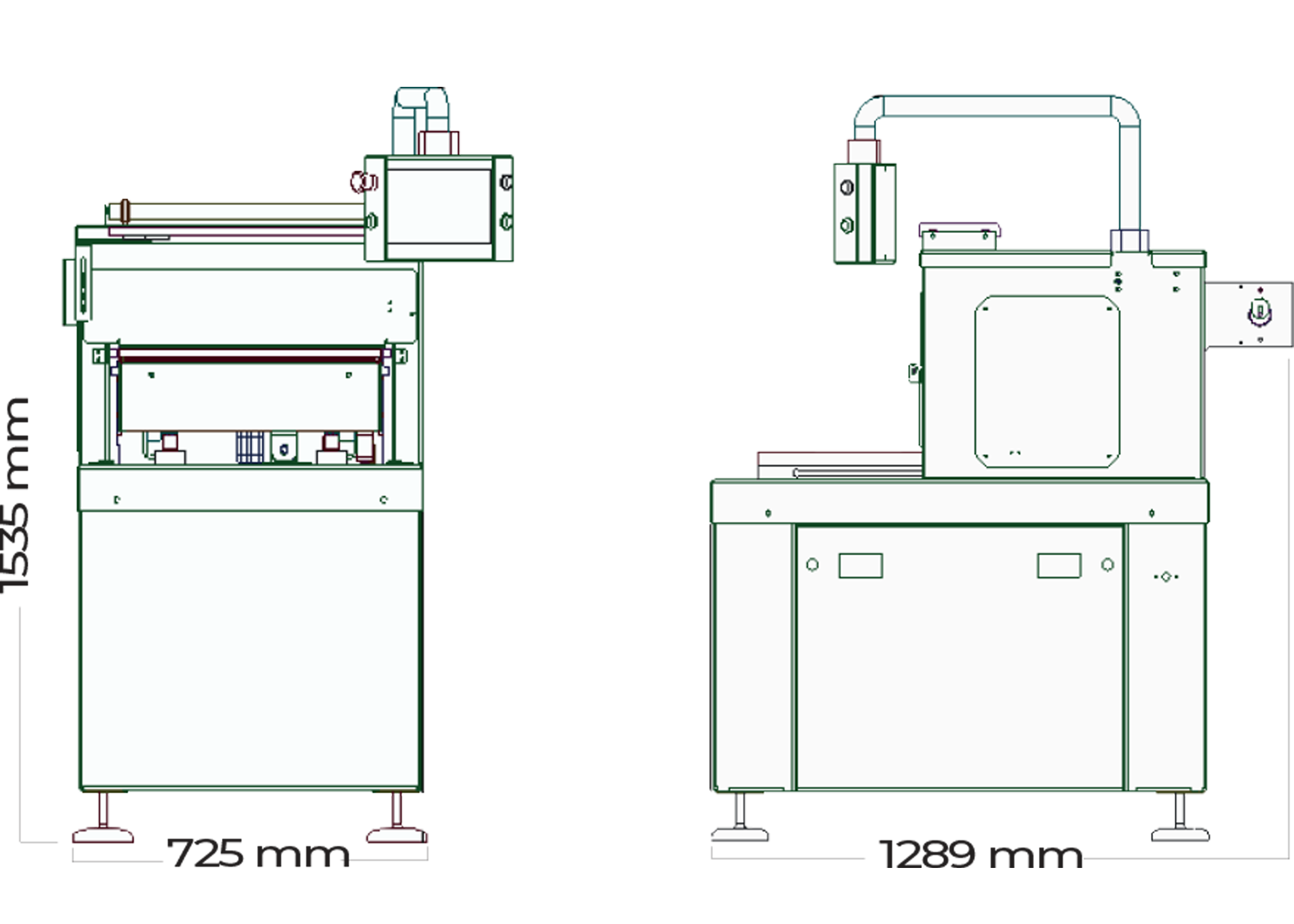

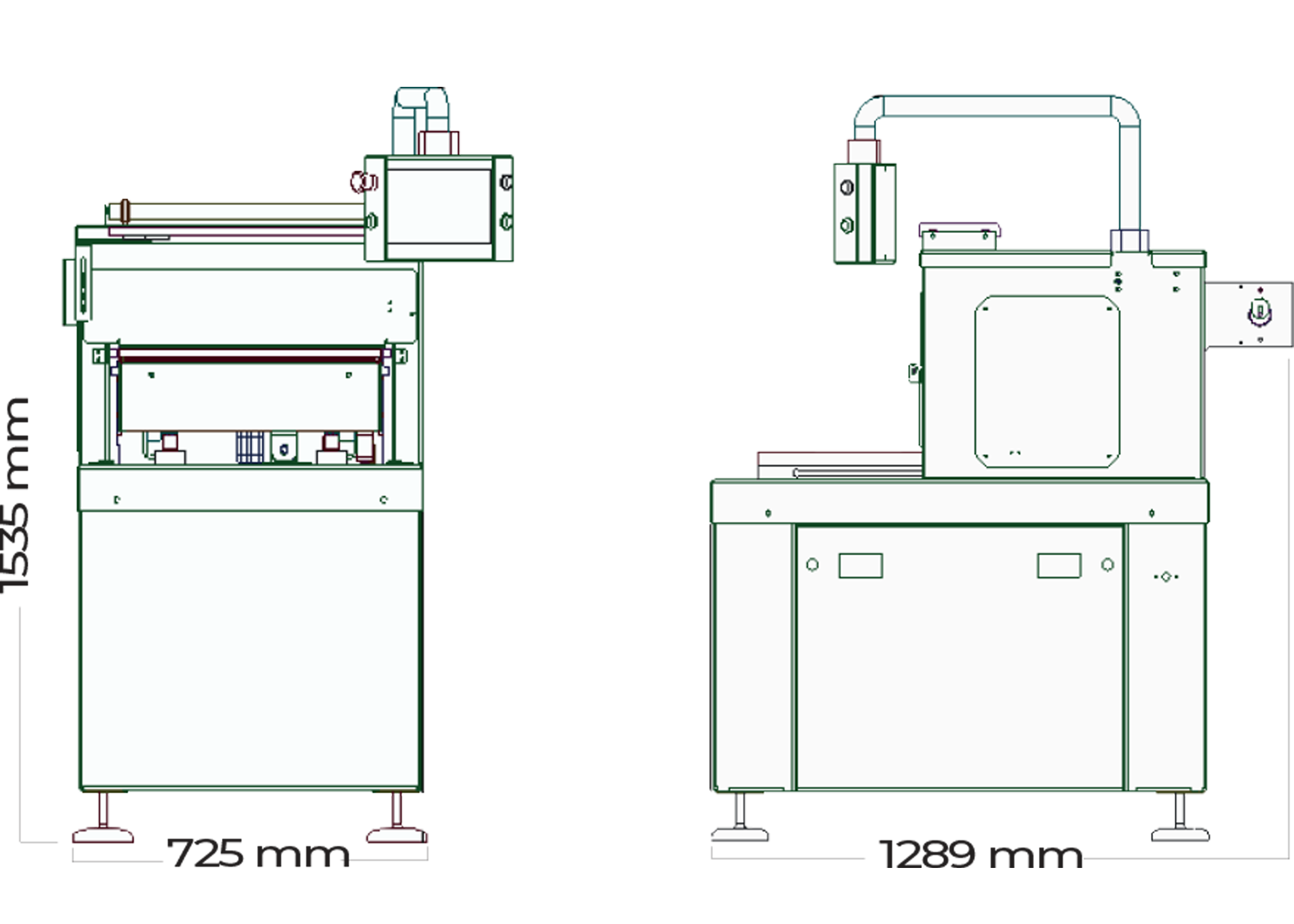

| Machine Dimensions |

725 X 1290 X 1585 mm |

| Max. Mold Dimensions |

495 mm x 420 mm Standard |

| Weight Net/Packaged |

300/360 KG |

| Max. Plate Depth |

120 mm |

| Max. Film Width |

500 mm |

| Min. Film Thickness |

40 Mic |

| Max. Film Weight |

12-15 Kg |

Features

| Vacuumed and gaseous tray sealing feature |

| Soft vacuuming opportunity with soft air option |

| 10-inch Touch Screen operator panel screen operator panel and adjustable panel box |

| Aluminum parts are of imported 5083 aluminum (eloxal coated) |

| Mold system is of imported 7075 aluminum (eloxal coated) |

| Values are monitored numerically and graphically |

| Vacuum pump (standard 100 m3) |

| Error-free mobility with drawers having linear sliding system |

| Precise measurement with absolute vacuum sensor |

| Possibility of only welding and cutting by one-touch |

| Stainless steel body of quality 304 |

| Automatic and manual drawer options |

| 8 different language options |

| Time saving with pneumatic and quick mold system |

| Completely cut the film around the plate and does not need extra labor |

| Energy saving with automatic temperature control system (PID) |