VTK 200 TT

Completely made of stainless steel, the mold and aluminum parts are eloxal coated. Values can be monitored both numerically and graphically using the touch operator panel, which enables easy operation. The pneumatic system, gas pressure, and vacuum values are regulated by sensors on the machine, and the operator is guided by warning messages displayed on the 7-inch screen. The machine offers unlimited mold choices and high performance, facilitated by an easy-to-replace mold system. Safety is ensured by adherence to CE standards. The machine automatically switches to stop mode during the installation of the film or the replacement of the mold, thanks to the security sensors.

Description

Description

Types of packaging

| Sealing Only |

| Map |

Packaging products

| Dry Fruits And Snacks |

| Baking |

| Fruits And Vegetables |

| Ready Meals |

| Fresh Meats |

| Cheese And Dairy Products |

| Cold Meats |

| Fresh Noodles |

| Sliced |

| Fish |

Technical Specifications

| Tray Options | |

| PP | Yes |

| PET | Yes |

| Paper | Yes |

| Sealing Options | |

| Film | Yes |

| Paper | No |

| Skin | No |

| Map | Yes |

| Vacuum | Yes |

| Installed Power | 220v 50 Hz 16a |

| Vacuum Pump | 20 M3 |

| Energy Consumption | 1,8 Kw |

| Air Pressure | Max 6 Bar |

| Air Consumption | 3.5 Lt Cycle |

| Capacity/min | 10-12 Process |

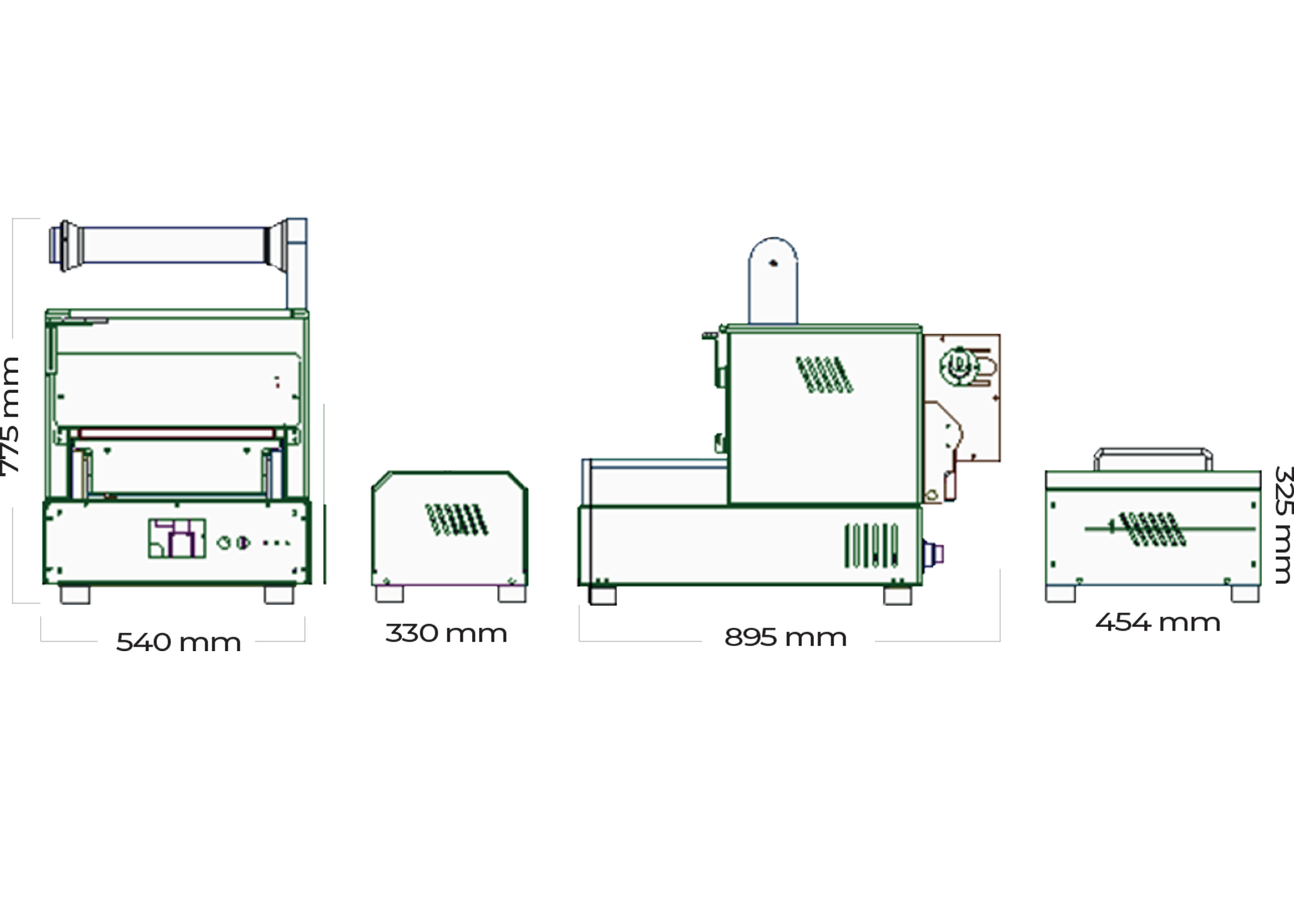

| Machine Dimensions | 748 X 583 X 973 mm |

| Max. Mold Dimensions | 349 mm X 280 mm |

| Max. Plate Depth | 100 mm |

| Max. Film Width | 350 mm |

| Min. Film Thickness | 30 Mic. |

| Max. Film Weight | 12 Kg |

Features

| Vacuumed and gaseous tray sealing feature. |

| Soft vacuuming opportunity with soft air option |

| 5-inch Touch Screen operator panel |

| Aluminum parts are of imported 5083 aluminum (eloxal coated) |

| Mold system is of imported 7075 aluminum (eloxal coated) |

| Values are monitored numerically and graphically |

| Vacuum pump (standard 20 m3). |

| Easy using and moving to vacuum pump stainless still box |

| Precise measurement with digital vacuum sensor |

| Possibility of only welding and cutting by one-touch |

| Stainless steel body of quality 304 |

| Teflon-coated mold system |

| Photocell unit to use printed film (optional) |

| Time saving with pneumatic and quick mold system |

| Completely cut the film around the plate and does not need extra labor |

| Energy saving with automatic temperature control system (PID) |

Related products

Reach out to us for a demo.

Speed up your operations with this environmentally responsible, surprisingly affordable, and elegant package.

Artisan Container LLC

3382 Commercial Avenue

Northbrook, IL, 60062

+1 872 248 9470

sales@artisancontainer.com

© ArtisanContainer.Com