Showing 17–20 of 21 results

-

VTK 400 TT

The mold and aluminum parts are eloxal coated. Values can be monitored both numerically and graphically via the touch operator panel, simplifying operations. The pneumatic system, gas pressure, and vacuum values are controlled by sensors on the machine. The operator is directed by warning messages displayed on the panel. The machine is equipped with options for both printed and non-printed film, as well as a photocell system. It offers unlimited mold choices and high performance, thanks to an easy-to-replace mold system. Safety is ensured by compliance with CE & EAC standards.

-

VTK 500 Smart

The mold and aluminum parts are eloxal coated. Values can be monitored both numerically and graphically via the touch operator panel, simplifying operations. The pneumatic system, gas pressure, and vacuum values are controlled by sensors on the machine. The operator is directed by warning messages displayed on the panel. The machine is equipped with options for both printed and non-printed film, as well as a photocell system. It offers unlimited mold choices and high performance, thanks to an easy-to-replace mold system. Safety is ensured by compliance with CE & EAC standards. The machine automatically switches to stop mode during the installation of the film or the replacement of the mold, aided by security sensors.

-

VTK 500 Smart-SP

The mold and aluminum parts are eloxal coated. Values can be monitored both numerically and graphically via the touch operator panel, simplifying operations. The pneumatic system, gas pressure, and vacuum values are controlled by sensors on the machine. The operator is directed by warning messages displayed on the panel. The machine is equipped with options for both printed and non-printed film, as well as a photocell system. It offers unlimited mold choices and high performance, thanks to an easy-to-replace mold system. Safety is ensured by compliance with CE & EAC standards. The machine automatically switches to stop mode during the installation of the film or the replacement of the mold, aided by security sensors.

-

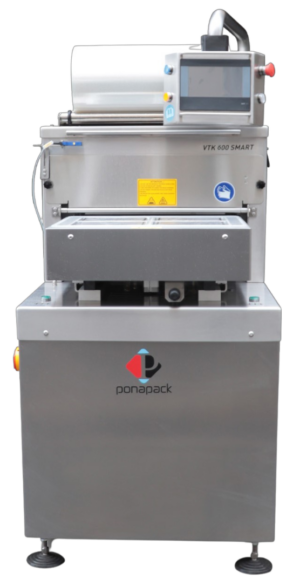

VTK 600 Smart

The mold and aluminum parts are eloxal coated. Values can be monitored both numerically and graphically via the touch operator panel, simplifying operations. The pneumatic system, gas pressure, and vacuum values are controlled by sensors on the machine. The operator is directed by warning messages displayed on the panel. The machine is equipped with options for both printed and non-printed film, as well as a photocell system. It offers unlimited mold choices and high performance, thanks to an easy-to-replace mold system. Safety is ensured by compliance with CE & EAC standards. The machine automatically switches to stop mode during the installation of the film or the replacement of the mold, aided by security sensors.